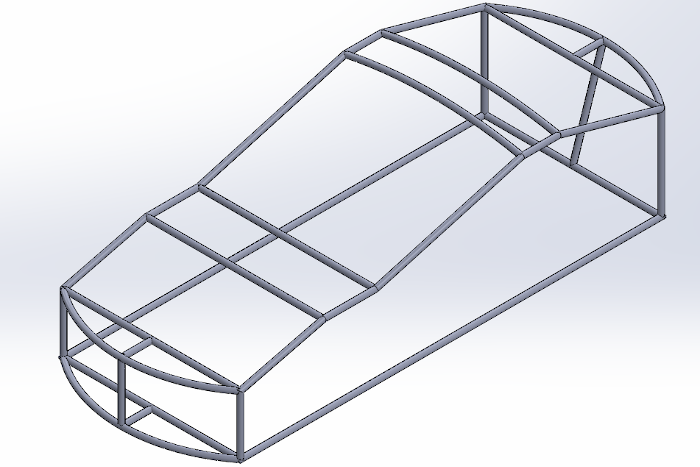

Aeroshell Frame

I used to take part in the McMaster Solar Car Project (MSCP) at McMaster University as the Chassis Team Lead. The team researches, designs, and builds aerodynamic, solar powered, endurance race vehicles. During a race, we go as far as we’re able to with only the pre-charged battery power and the whatever extra charge we can get from the panels as we go, assuming we don’t break down first. If you want to find out more about the team, this is the MSCP website.

While I was Chassis Lead, the team switched from Challenger Class to Cruiser Class. The Challenger Class had been the most popular class for a long time, but the Cruiser Class was growing in popularity and a lot of other teams had already made the switch. This new class was very different from what we were used to so we had to do a lot of research on how these cars usually look and how the best teams usually perform.

The team decided to model the new car after a Jaguar F Type. The aeroshell was already designed and other team members were working on the occupant cell (where the driver and passenger sit), my job was to design the connection between these.

I designed a skeleton frame to which the occupant cell, aeroshell, and parts of the suspension mount. This skeleton is designed to sit on top of our chassis and provide an easy connection point for the aeroshell that can resist and transfer any downforce generated. The skeleton frame will be securely mounted to the chassis and the suspension, then the aeroshell drops on top and attached with u-bolts.

I designed this frame using the weldments feature in SolidWorks. Using the aeroshell CAD as a guide, I used 3D sketches and traced the contours of the shell with lines. I used weldments to create the tubular frame. The frame is made of 1.25”OD by 0.095”THK 4130 Chromoly Steel Tube. I chose 4130 because it has a great strength to weight ratio and is already a popular for chassis and rollcages. The specific diameter and wall thickness of the tubing, although also popular, was chosen for its stiffness and strength to weight ratios.

Honestly, the frame is not a very good design right now. There is a large lack of support in the middle section and no good place for the suspension to connect. The team was struggling to get the aerodynamic drag coefficient low enough on the aeroshell and went in a different direction.

If the aeroshell had remained this shape, the next steps would be changing the front and rear design to accommodate the front and rear suspension, add more support overall, and look into optimizing the design for manufacturing by combining tube sections to minimized welding.

Also check out the rollcage I designed in my first year on the team!